The logistics sector is facing a capacity challenge. While e-commerce continues to skyrocket, companies are struggling with a chronic shortage of labour. In the Czech Republic, warehouse workers account for 64% of all advertised logistics job positions. The solution is a massive wave of robotisation. A recent survey among Czech companies confirms this accelerating trend: according to the study, 99% of respondents plan to introduce at least partial automation in logistics within the next five years.

Smarter, Faster, and More Flexible AMRs

The key technology driving this transformation is Autonomous Mobile Robots (AMR). Unlike older AGV (Automated Guided Vehicle) systems that follow magnetic floor tapes, AMRs use LiDAR sensors, 3D cameras, and SLAM (Simultaneous Localisation and Mapping) technology to create a digital map of the warehouse. This allows the robots to dynamically avoid obstacles, whether it’s a misplaced pallet or a passing worker. Their deployment is significantly faster and requires no costly building modifications.

Real efficiency, however, comes with deploying an entire fleet of autonomous robots working together as a single intelligent organism. This is managed by a Fleet Management System (FMS), which controls and coordinates groups of AMRs or AGVs within logistics and manufacturing environments. FMS handles task allocation, traffic control, charging management, analytics, and reporting.

Hard Data: Productivity and ROI

The benefits of warehouse automation are both measurable and substantial. “Goods-to-Person” systems, where robots bring items directly to operators, eliminate up to 85% of unproductive walking time in warehouses. Alza has quadrupled its order dispatch speed by deploying more than 400 robots. Vermont reduced its seasonal labour demand by 50% thanks to automation. Typical return on investment ranges between 1 and 3 years.

A good example is the Authentica Fulfillment warehouse near Brno, where a €3 million investment into 63 robots is expected to pay off within three years. The robots can operate 24/7 and travel 30–50 km per day, a distance nearly impossible for a human worker with a pallet jack to cover.

Czech Innovation and the Future of Work

Robotisation is not just for global giants. The Czech Republic already boasts fully automated warehouses, such as Dextrum Fulfillment in Paskov. Another impressive example is Archeion, a unique high-capacity storage system developed by the Technical University of Liberec.

For reliable coordination of dozens of robots, private 5G networks are increasingly being used. Compared to Wi-Fi, they offer higher stability and lower latency. One such example is the Paskov warehouse, where a 5G network from T-Mobile ensures seamless communication across the robotic fleet.

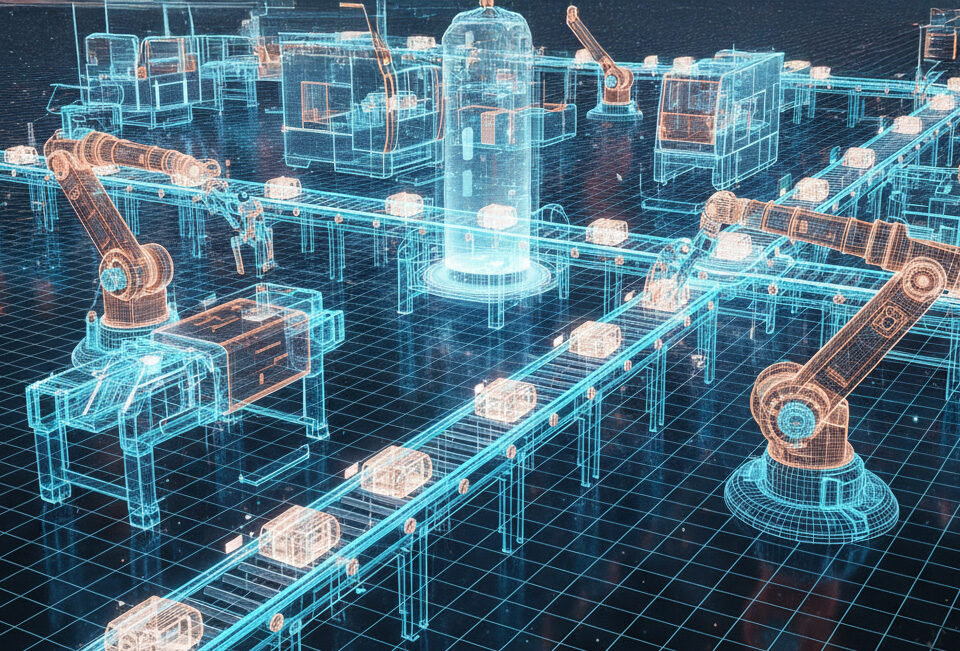

The future of logistics will be shaped by increasing levels of intelligence. Artificial Intelligence (AI) will play a key role in advanced route optimisation and predictive maintenance. Digital twins – virtual replicas of warehouses – are also gaining importance, allowing companies to test and optimise processes without disrupting real operations. In the longer term, the deployment of humanoid robots is on the horizon. Are you planning to automate or robotise your warehouse or production facility? Let’s talk about your project, we’re ready to help you shape your digital transformation.