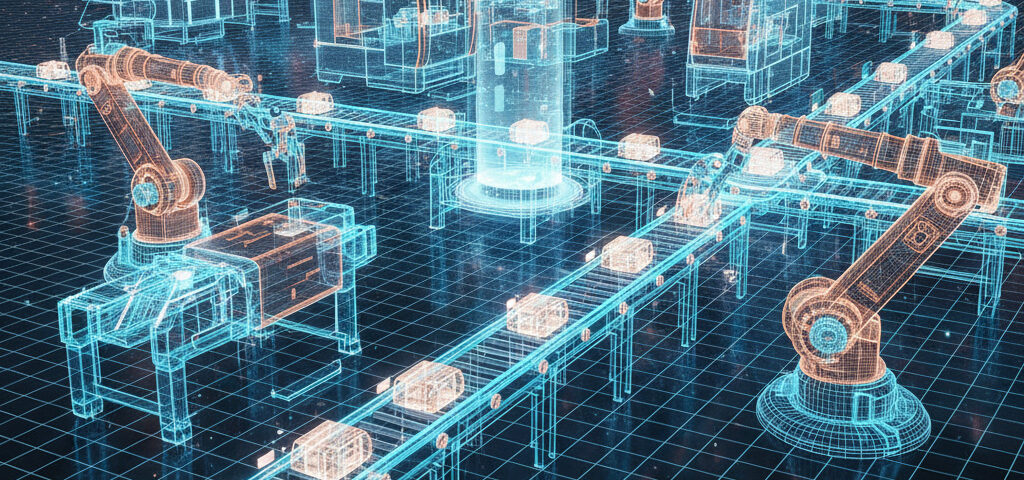

Imagine being able to test production changes, predict machine failures, and optimise entire processes, all without touching a single piece of physical equipment. This is the reality of digital twin (DT) technology, now a cornerstone of Industry 4.0. It is not just a passing trend but a massive and ongoing market transformation. Analysts predict that the global DT market will grow from USD 5 billion in 2019 to USD 154 billion by 2030.

What Is a Digital Twin and How Does It Work?

A digital twin is a living, dynamic virtual replica of your production line, or even your entire plant. It is continuously updated in real time through sensor data collected from physical machines. This data is analysed to run “what-if” simulations without any risk to actual operations or production downtime. By combining the digital twin (the brain) with process automation (the muscles), an intelligent, self-optimising system is created. The twin identifies the optimal procedure, and the automation systems execute it accordingly.

From Virtual Model to Real Operation

At EA Partner, we begin by creating a digital, kinematic model of the workstation to verify the process and technical feasibility of the machine’s original concept. We then release the manufacturing data (CAD data for production tools) and prepare offline programs that serve as the machine’s baseline setup. Due to variations in component quality, surface treatments, or deformations, some adjustments may be required in the machine settings — which we then transfer back into the DT model. This enables us to simulate further changes, additions, or production program modifications based on real, achievable data. Such know-how is particularly crucial in designing robotic welding lines, both for arc and resistance welding.

In some cases, we even create digital twins through reverse engineering, importing operational settings and inputs from external CAD formats to generate a DT model. This allows us to test the feasibility of process changes or integrate new products. However, this is a costly and rarely used method in practice.

Tangible Results in Practice

The key benefit of digital twins lies in accelerating development and planning. The Danish window manufacturer VELUX increased productivity by 40% and reduced planning time by 70%. Festo shortened new machine development time by up to 30% through virtual simulation. BMW uses digital twins of entire factories, improving production planning efficiency by 30%. Its virtual plant integrates data from over 40 different IT systems. And there are many more real-world examples.

The Future Is Digital and Autonomous

The industry is undergoing a fundamental shift toward intelligent, predictive, and self-optimising production with digital twins at its core. The next logical step in this evolution is the integration of artificial intelligence (AI), which will enable digital twins not only to recommend changes but also to implement them autonomously. According to Gartner, by 2027 up to 40% of large industrial enterprises will use digital twins to increase their revenues.

This technological symbiosis empowers companies to boost efficiency and reduce costs, while optimising operations, accelerating innovation, and enhancing resilience. In the era of Industry 4.0, investing in this technology is no longer just a competitive advantage. It is a necessity for staying relevant. Sensor data and cloud platforms have become new strategic assets. Organisations that embrace these principles will unlock the full potential of this symbiotic revolution. If you are planning to secure a digital future for your manufacturing operations, we are here to help.